Strategic Partnerships: A key to Future Success

In today’s world, defending freedom has taken on an entirely new look. Technology continues to accelerate at a very rapid pace, making it difficult for our military forces to maintain an edge on the rest of the world.

Companies like Lockheed Martin, Northrup Grumman, Raytheon and Boeing just to mention a few are now partnering up to create solutions for the needs of our military.

In the field of radar detection and monitoring, missile guidance, UAV / UAS development and a vast array of mobile communications technologies required to keep a battalion of troops communicating securing on the battlefield, companies are teaming up to provide the optimum solution to our military’s needs.

With this continual advancement in technology comes the ever-increasing costs to produce these specialized, high-speed thoroughbred systems. Twenty-year-old VMEbus crates no longer provide the high-speed data throughput that is available on 3U and now 6U VPX systems. High-speed vison-based sensors send more images back than many storage devices can hold after a short period of recording during test flights! FPGAs (Field Programmable Gate Arrays) and I/O products are evolving almost annually to keep up with the algorithmic requirements, making instantaneous decisions based on that accumulated data.

As head of sales for a small technology-based company, I found the difficulty in plotting a course for success in this highly competitive market very challenging. Our company has been in business over 60 years and has evolved into a leader in general purpose I/O products, expanding globally with a solid sales channel. We focus primarily on the MIL-AERO and Defense industry and the solutions that are developed in that market are based on four basic elements (as we see them) that encompass the heart of these technical solutions. They are CPUs, SFF Box Solutions (Small Form Factor), highly specialized board-level FPGA solutions (i.e. software radio, high-speed graphics, high-speed analog I/O, MIL-STD 1553, etc.) and general-purpose analog and digital I/O modules.

Each one of these four elements has many companies dedicated solely to the development and support of a family of products that fit various requirements within their respective element. This requires millions of dollars annually to keep up with the needs requested by the companies mentioned in my opening statement. There are a few that have been successful at all four (and a few that have tried and lost) but for the most part, technological advancement succeeds best in a “creative environment” that typically comes from smaller, more focused companies. So how does the “little guy” survive (better yet, thrive) in this environment?

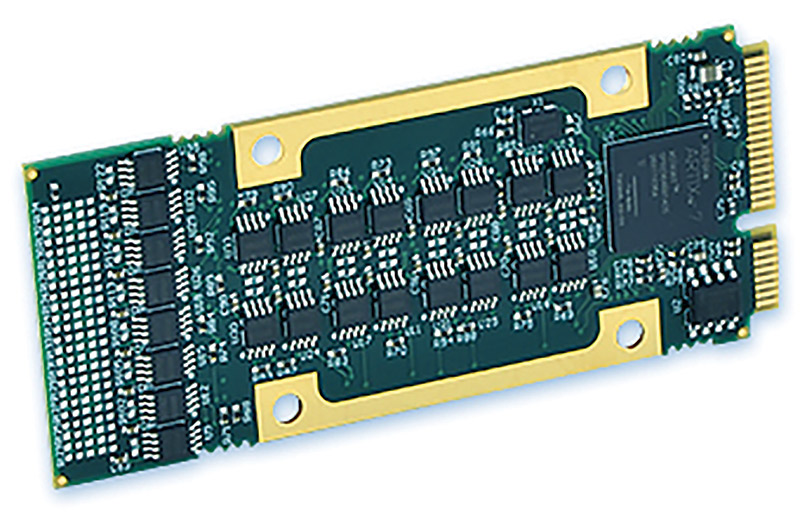

We found that by staying focused on what we do best, it has allowed us to create a new general purpose I/O platform, perfect for our market’s current and future needs. Using PCIe as a critical interface requirement, we took the mini PCIe concept up to the next level by extending the PCB 19mm and adding a 100pin connector to the opposite end and side of the board (see ill#). This allows us to run signals in and out of the FPGA controller and board logic without the need for any cables and providing additional feature capability on each board.

Whether the board contains analog, digital, programmable FPGA logic or serial communications, each one is designed using SMT components that provide a small footprint, low power consumption (less than 5 watts) and very little weight (excellent SWAP factor). The majority of them function in -40 to +85C and MIL-STD 810 environments. We call them AcroPacks (see figure 1).

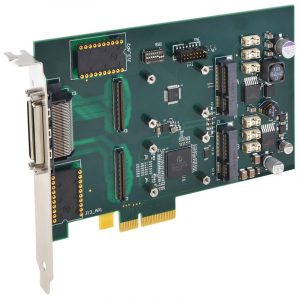

Once a family of I/O products were in design, efforts turned to carrier cards to provide homes for them in a variety of PCIe-based systems. This is where the future of the plan had to contain clear definition for success. Analyzing the market led to the clear identification of rugged servers and VPX systems as our first two strategic partnership potentials. Creating single-height, double-height ½ length and double-height full length PCIe carriers allows rugged server companies and integrators (using rugged servers) to add a huge variety of I/O on single, double and four-site I/O carriers (see figure 2). After addressing the servers, the next logical choice was VPX.

The 3U conduction-cooled format does not allow for more than a single I/O module to communicate thru the backplane, due to a limited number of pins available. However, on air-cooled applications we can support three I/O modules. It took very little time to realize that we could really provide optimal general purpose I/O flexibility on the 6U VPX platform (see figure 3). This form factor allowed for much higher data throughput speeds but has always been more expensive on a per-slot basis than 3U VPX. With the opportunity to create a 6U VPX carrier that handled an XMC site and four of the AcroPack products, I realized the potential would be even greater if the XMC site could host an XMC/SBC board. Once our design engineer confirmed it was possible, we completed and tested the design with XMC/SBC boards from both Curtiss Wright and Concurrent Technologies. CCT has also exercised the combination successfully as well (see figure 4).

This capability now allows an end user to select an XMC/SBC that meets their needs and install it on the 6U VPX carrier along with four additional I/O modules (including programmable FPGAs) and have a single-slot 6U VPX solution. Using a second and even a third carrier with additional I/O modules, other specialized XMC cards can be added (multi-channel high speed communications, software radio, high-speed analog I/O, custom graphics and video, etc.) to create a 2-3 slot 6U VPX solution that would rival a 5-8 slot 3U VPX system in price, yet out perform it by several times! Its overall package size could be smaller as well.

Continuing on this path, we are doing additional partnerships using the AcroPack family of I/O for COMM Express TYPE 10. Our ACEX-4041 carrier will accept a CPU from ADLINK and handle four AP I/O modules and M.2 storage. Our Channel Partner in France, Ecrin is developing a fanless SFF solution using #38999 connectors and removable storage for extreme applications based on a similar CPU/carrier combination (see figure 5).

In conclusion, smaller companies that stay focused on their core technologies can find success in this high technology world by adopting a strategic partnership approach. Partners that complement each other’s product lines offer up another way to expand market share together. It also provides significant benefit to the market customers by creating an improved price/performance solution for many of their applications. We are finding that by maintaining a win-win attitude with our partners, it can be done!